Axle Week

When it rains it pours. One of my favorite “clean” jobs are replacing axle joints or boots. There is nothing better than getting absolutely covered in grease, and take everything you touch with you, lol.

A freind of mine noticed he had a couple of torn axle boots on the rear of his 993 that needed attention. It is very important to replace these boots if you notice them ripped at all, as they no only help to keep the grease in the joint, but also keep out the dirt and contaminants from getting into the joint and ruining it. If you catch them early, you can usually save the joints. The boots are a heck of a lot cheaper than replacing the joints or the entire axle. Now on a standard transaxle on the 993, getting the axles out to replace the boots isn’t hard as there is room to slide them out. On a tiptronic unfortunately, the transaxle is much wider, which prevents ease of axle removal. I am pretty sure I heard Tim yell Merry Christmas as he walked away laughing. Yee Haw.

In the air.

Here you can see a tear in the boot (just past the shock)

Yup….can’t see the axles anymore can you, lol….well they are still there.

Disconnected from the transaxle. No clearance to come out the middle.

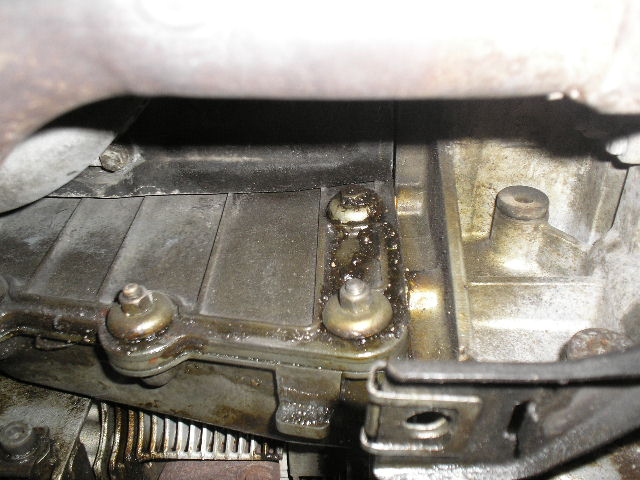

While I pondered the axle removal, I decided to replace a couple of the chain cover washers since they were leaking oil. Figured we would try and at least slow down some of the leak.

Bolt removed with washer.

Old washer. Over time these rubber washers will shrink and start to cause a leak. You might be able to retorque the bolts, but you really should replace the washers if you can.

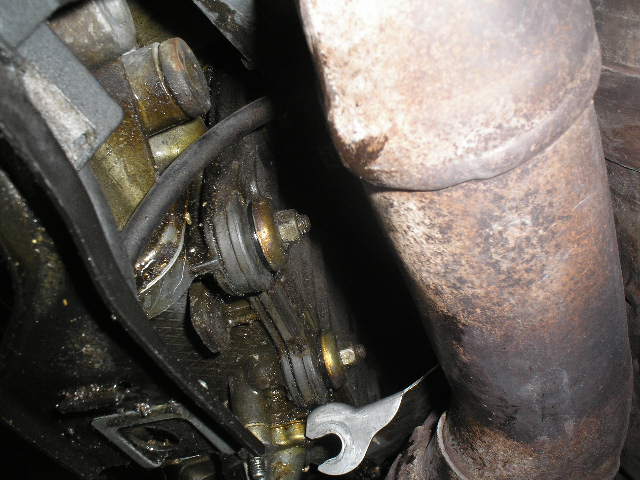

Passenger side is a little harder to get to due to a heat shield.

Anyway, back to the axles. So the rear multilink suspension needs to come completely apart to get the axle out. I carefully marked the eccentric bolts, but it will still need an alignment.

The pile of tools grows.

Passenger axle out of the car. The joints seemed like they were still in good shape, so a thorough cleaning and regreasing, along with new boots and we should be in business. Note: Use cardboard, you will thank me later.

Removing the joint. It takes a big puller to slide the joint off the axle shaft.

Cleaned up and inspected. Nothing out of the ordinary. You can completely disassemble the joints to inspect the ball bearings and the surfaces they ride on.

Outer joint is not servicable though. Pack some grease in there and go!

Then it was on to the driver’s side. We had 3 ripped boots, so we had to do them all. Same procedure. Same results. Back in business.

One Comment

Leave a commentDavid Lessmann

December 22, 2010 at 11:54 AM

Tim needs to sandblast and paint his rotors. 😉